At Shadow Industrial, we strive for excellence when it comes to providing warmth in industrial spaces. Our business stands out as a beacon of innovation and practicality. We offer revolutionary heating solutions that transcend the limitations of traditional warm air heating methods. In warehouses particularly, our infrared heaters have proven transformative, addressing challenges in ways that conventional systems fall short. The following case study delves into an instance where our industrial infrared heaters brought warmth and efficiency to a large warehouse. The company had been seeking an efficient and eco-friendly heating solution, as their old system was neither effective nor cost-efficient. From overcoming freezing conditions to ensuring worker comfort and productivity, our heaters emerged as a cornerstone solution, showcasing the unique benefits they bring to industrial warehouses.

Effectively heating a large open building presents unique challenges, especially in spaces with limited insulation and susceptible to heat loss through draughts or intermittent use. Shadow Industrial's infrared heating solutions address these challenges.

Our heaters utilise the most advanced shortwave heating technology, emitting focused radiant heat from precision-engineered Ultra Low Glare lamps and mirror quality parabolic reflectors. When directed downward, the heat creates a comfortable and instant warmth, precisely mimicking the gentle heat of the sun. Ideal for industrial sites, as well as culturally significant historic buildings, our heaters instantly reach optimal temperatures. They remain unaffected by changes in air movement, such as draughts or within less-insulated spaces. Each heater or group of heaters can be utilised exactly when needed, providing not just optimum warmth but also significant energy cost savings.

Howmet Aerospace is a leading producer of components for aero engines and industrial gas turbines, as well as fastening systems and various engineered structures. The company is committed to advancing the sustainability of their customers and the markets they serve through innovative engineering and operational practices. Howmet focuses on minimising environmental impact by reducing emissions, conserving energy and water, eliminating waste, and creating products that support these goals.

Howmet Aerospace faced significant challenges with their existing heating system, which was based on gas-fired air blowers. This system was not only inefficient but also costly to operate, leading to high energy consumption and expenses. The company sought a solution that would enhance their heating efficiency, reduce energy consumption, and align with their sustainability goals.

Howmet Aerospace aimed to achieve several key objectives with the implementation of industrial infrared heating solutions:

To address Howmet Aerospace's needs, we proposed a comprehensive suite of infrared heating solutions.

The specific products and their specifications included:

These products were chosen for their high efficiency, reliability, and suitability for industrial applications. Customisations were made to ensure the heaters met the specific spatial and operational requirements of Howmet Aerospace.

Find out more about the rangeThe implementation process was carefully planned and executed to minimise disruption to Howmet Aerospace's operations. The timeline and key milestones included:

Key team members from both Howmet Aerospace and our side were involved throughout the project to ensure smooth execution and address any challenges.

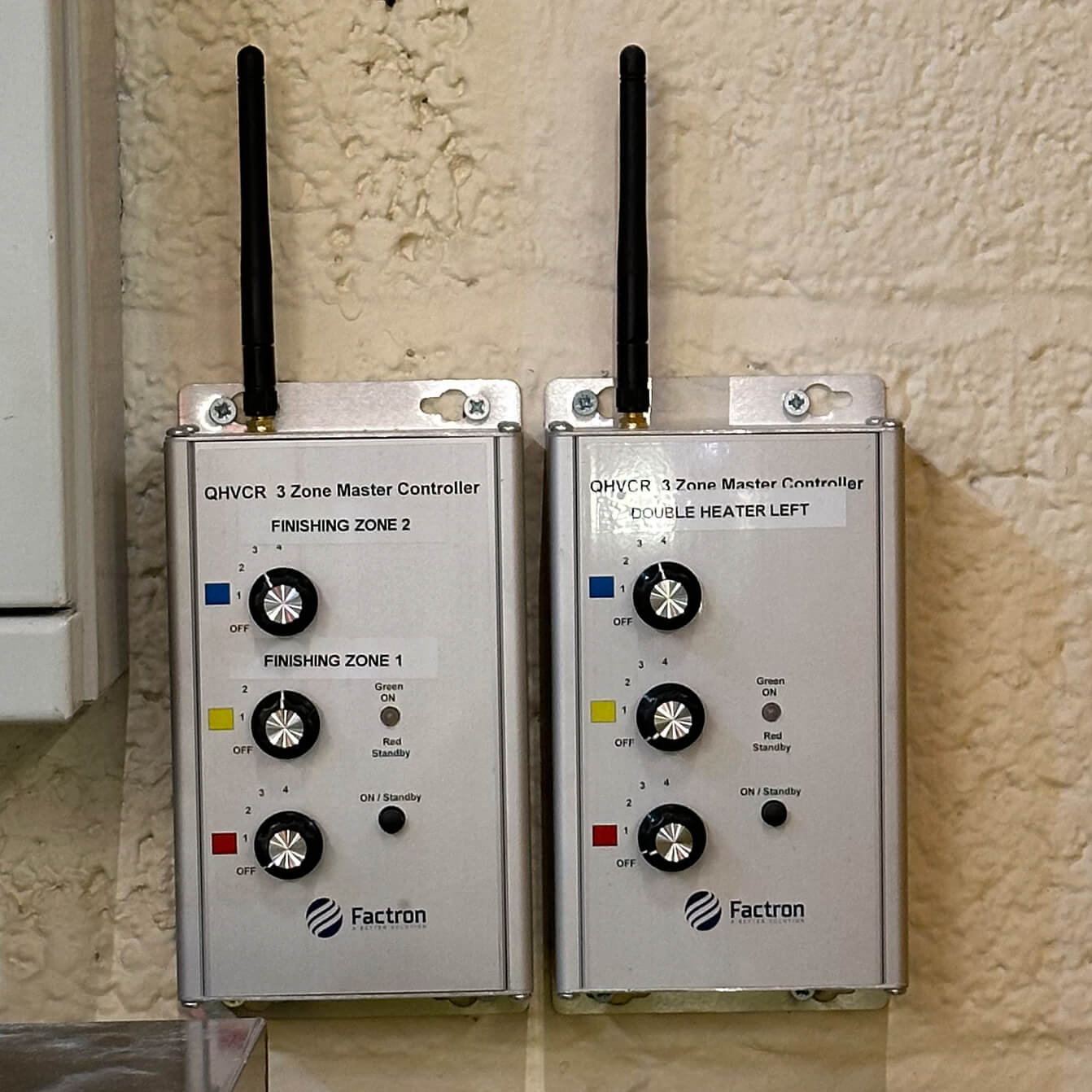

Our infrared heating solutions employed cutting-edge technologies to enhance efficiency and performance. The key innovations included:

Integration with Existing Systems: Seamlessly replacing the old gas system with our infrared solutions, resulting in significant improvements in efficiency.

The transition from gas-fired air blowers to infrared heaters marked a significant upgrade. By replacing the inefficient gas system, Howmet Aerospace was able to leverage our infrared heaters to achieve substantial energy savings and improved heating performance.

Howmet Aerospace expressed high satisfaction with the results. They highlighted the infrared heating project as their best-performing sustainability and efficiency initiative. The investment in the new system paid for itself in under a year, demonstrating the project's success.

Most companies today want to reduce or eliminate their net contribution to greenhouse gasses - but it can be hard to know where to begin.

What will have the most impact? One focus area for many organisations is their energy use and heating.

Gas-based systems are falling out of favour as they generate significant carbon emissions. Instead, many are turning to electric infrared heating as this offers the potential for zero emissions at the point of use if renewable energy is used to power them.

Infrared is a popular choice as it offers very high-efficiency ratings - up to 98% of energy is converted into heat. Additionally, heat isn't wasted as it can be focused on the areas that need it the most.